Using Lost Sales Information to Improve Availability

Most non-food retailers don’t measure availability and don’t estimate lost sales. Yet in grocery (where lost sales are measured more consistently) various studies have out them at 6 to 8% of sales. Non-food lost sales will be a lot higher as there is less year-round product, lower frequency of purchase, less time series data and tougher forecasting challenges. At Martec we reckon non-food lost sales are at least 15% or more. In the fashion world about half of all theoretical lost sales are eliminated due to substitution by the consumer. Hence 70 % availability at store / SKU level of granularity roughly equates to 15% lost sales through the season. Experience with our clients shows that it is feasible to get a 10% improvement in availability and every 1% improvement equates to 0.5% same store sales growth. A 10% improvement in availability delivers an average 5% sales growth which most retailers would relish.

Demand is the sales you made plus the lost sales you incurred, which you have to estimate as only online channels capture lost sales accurately and only then with good systems and processes. If you plan with sales history (without adding in demand) you repeat the mistakes or shortcomings of the past. For example, best selling sizes will run out of stock earlier in the season than you would mostly like. Planning and replenishing based on sales history will perpetuate this problem. You will under buy and mis-allocate as you did in previous seasons. Best practice is to estimate historic lost sales and then add the numbers to actual sales to get estimated historic demand. Then plan and allocate using historic estimated demand as your base line.

Estimating lost sales for continuity products is relatively easy. Average daily sales is calculated for an appropriate period of time up until an out of stock occurs. This daily sales rate is then multiplied by the number of days out of stock to give the lost sales estimate. If there is a slight trend, then a weighted average can be used.

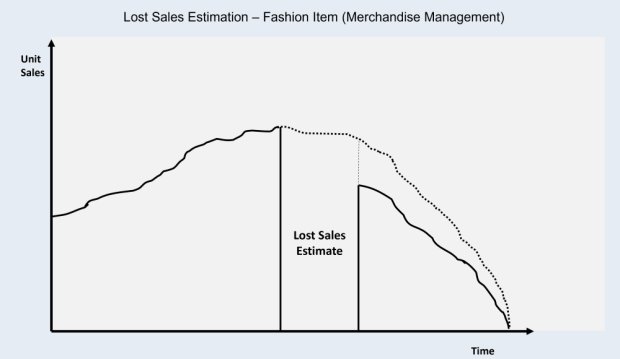

In a merchandise management environment, it is a little more complicated, due to the seasonal profile of the merchandise. Once a seasonal item goes out of stock, sales rarely recover to their previous level, when the product is back in stock. A proportion of consumers assume that the product is finished for this season.

Profiles are produced which reflect the anticipated sales pattern for the product in question. When an item goes out of stock in a store, the profile needs to be scaled up or down to reflect the season to date sales of the product concerned. The lost sales are then estimated up to the point when the store is in stock again using the profile. Thereafter, lost sales are estimated by the gap between the actual sales and the sales profile. The first part of the lost sales can be determined once the product is back in stock. The second part can’t be sensibly estimated till the end of the season and should be part of the end of season review.

The profit impact of lost sales recovery is really very dramatic. If you can recover half your lost sales, you can increase pre-tax profits by 30%!

If you’d like more best practice advice check out our forecasting and sales and inventory management e-learning classes.

-

Posted by Brian Hume

24th January 2025